This year’s Intergalva 2015 conference brought together some of the most prominent business and industry leaders in the global galvanizing industry, as well as distinguished academics and experts from universities, industry and other organisations including World Steel, International Zinc Association, Siemens Wind Power and Tata Steel Construction.

Held at ACC Liverpool, Kings Dock, Liverpool, 7-12 June 2015, some 500 delegates from over 50 countries attended the conference, which occurs every three years and is the leading international forum for the hot dip galvanizing industry. A theme of this year’s conference programme was Sustainable Energy, Infrastructure and Architecture.

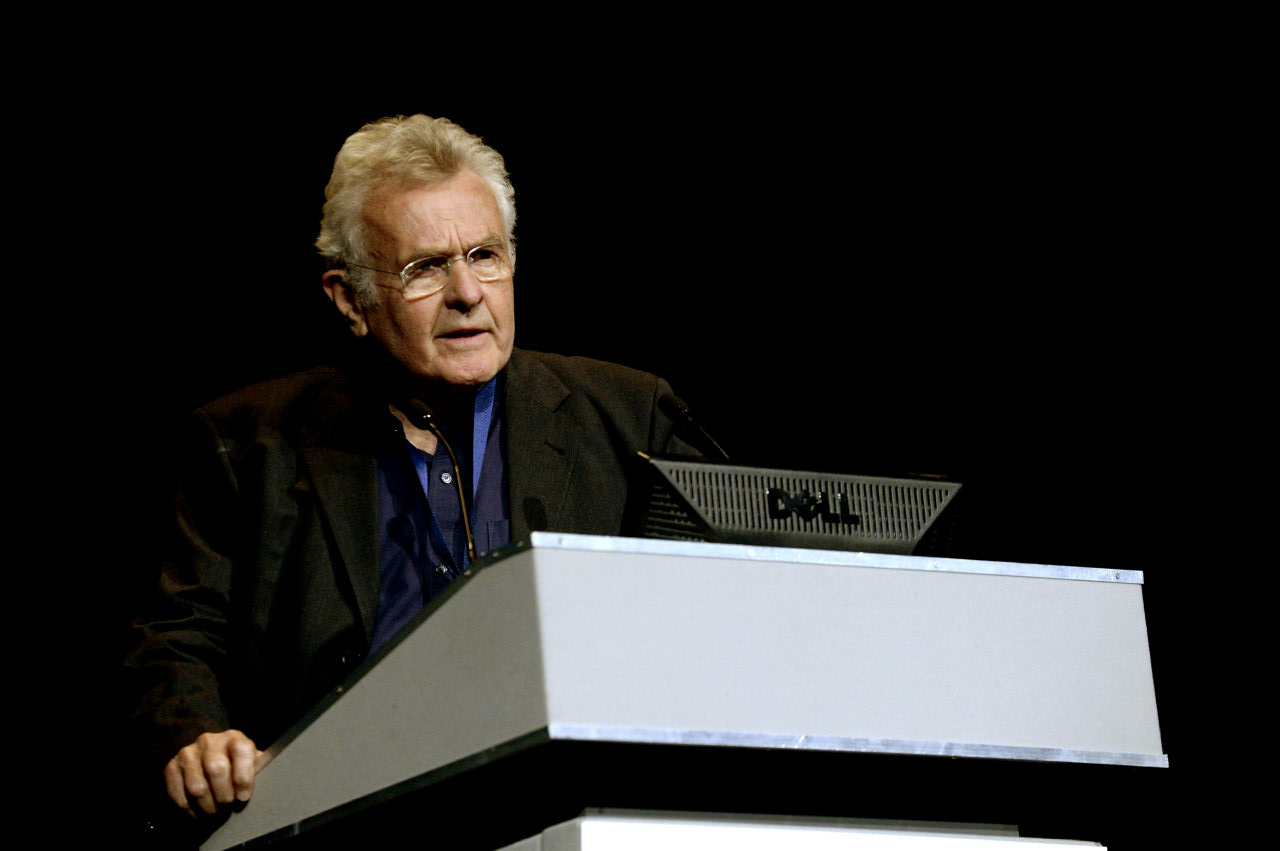

Digby, Lord Jones of Birmingham opened Intergalva 2015 and called on the audience of global galvanizing industry leaders to recognise their vital role in supporting socially-inclusive wealth creation. He also urged the delegates to continue to drive innovation and pursue growth in the galvanizing industry, whilst placing a firm and continued emphasis on the need for sustainable development across the industry.

Dr Basson also strongly emphasized galvanized steel’s compatibility with the concepts of a circular economy, saying that: “….the ease with which steel can be recycled and reused is not easily matched by competitor products. The thin layer of zinc on steel products has a negligible impact on the overall recyclability of the product. The zinc is also typically recovered from dust collection systems during steel recycling.”

Summing up Intergalva 2015, Mr Jeremy Woolridge CBE, President of the European General Galvanizers Association said that Intergalva 2015 had been extremely successful in terms of the range of high quality content as well as the new business developed and relationships strengthened. Mr Woolridge added: “Throughout the conference, the sustainable advantages of the galvanizing process and the endless recyclability of zinc were constant themes. Our speakers presented a range of case studies depicting the innovative ways in which galvanized steel is being used in more and more applications. In addition, there were also a number of important academic report papers and studies presented – each focusing on the environmental, and the long term, proven, commercial benefits of galvanizing’s sustainability properties over other protective anti-corrosion methods”.

The 2015 Global Galvanizing Awards were announced at Intergalva 2015. The Awards recognise the innovative use of galvanized steel by architects, engineers and steel constructors and this year there were a record number of entries from 16 countries.

Schulitz Architects’ Central Bus Station in Haldensleben (Germany) took the Judges Award with judge, Matthew Wells commending the project ‘Making full use of the advantages of hot dip galvanizing and structural gymnastics of the structure’. In accepting the award, Prof Helmut Schulitz explained “Our client wanted a sustainable building and to avoid future maintenance. For this reason the client quickly accepted our proposal for a hot dip galvanized structure.”

The roof structure of the Vienna Railway station was voted as the Industry Award winner. Project architect, Michael Frischauf accepted the award on behalf of Albert Wimmer ZT – GmbH architects and gave an enthralling presentation of the project and explained the importance of galvanizing of the 7000 tonnes of structural steel comprising the roof supports as these would have limited access for future maintenance.

Intergalva 2018 will be held in Germany in June 2018.