Photo credit: Ahlbrecht-Felix-Scheidt

Photo credit: Ahlbrecht-Felix-Scheidt Photo credit: Ahlbrecht-Felix-Scheidt

Photo credit: Ahlbrecht-Felix-Scheidt Photo credit: Ahlbrecht-Felix-Scheidt

Photo credit: Ahlbrecht-Felix-ScheidtPig iron first flowed from the blast furnace of the St. Antony ironworks in 1758. Today, this first ironworks in the Ruhr region is part of an industrial archaeological park.

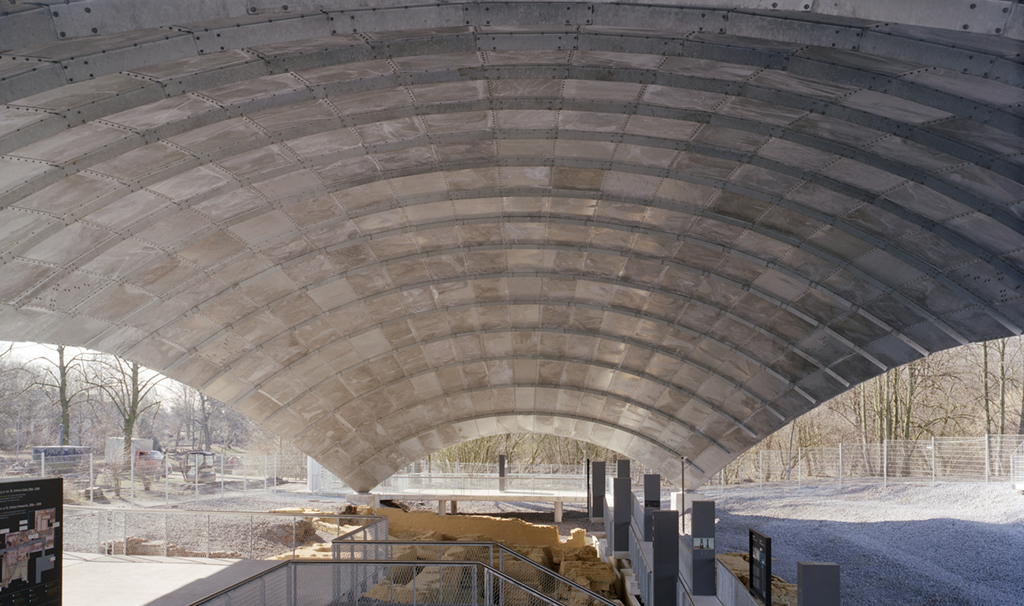

The architects have designed a structure to mark the historical significance of the location. Their solution was a minimalist steel roof that both protects yet adds an almost temporary feel to the site. The roof shell lies exposed over the main sections of the archaeological dig where visitors can learn about the ironworks – the ‘cradle of the industrial Ruhr’.

The 900 m2 shell roof has 323 similar, but not identical, panels which overlap each other like shingles. Due to their double-curved shape and rigidity, the shell is self-supporting and needs no welding. Hot dip galvanizing the steel panels has provided long-term, sustainable corrosion prevention and also creates a lively surface which lends the structure the desired technical charm.